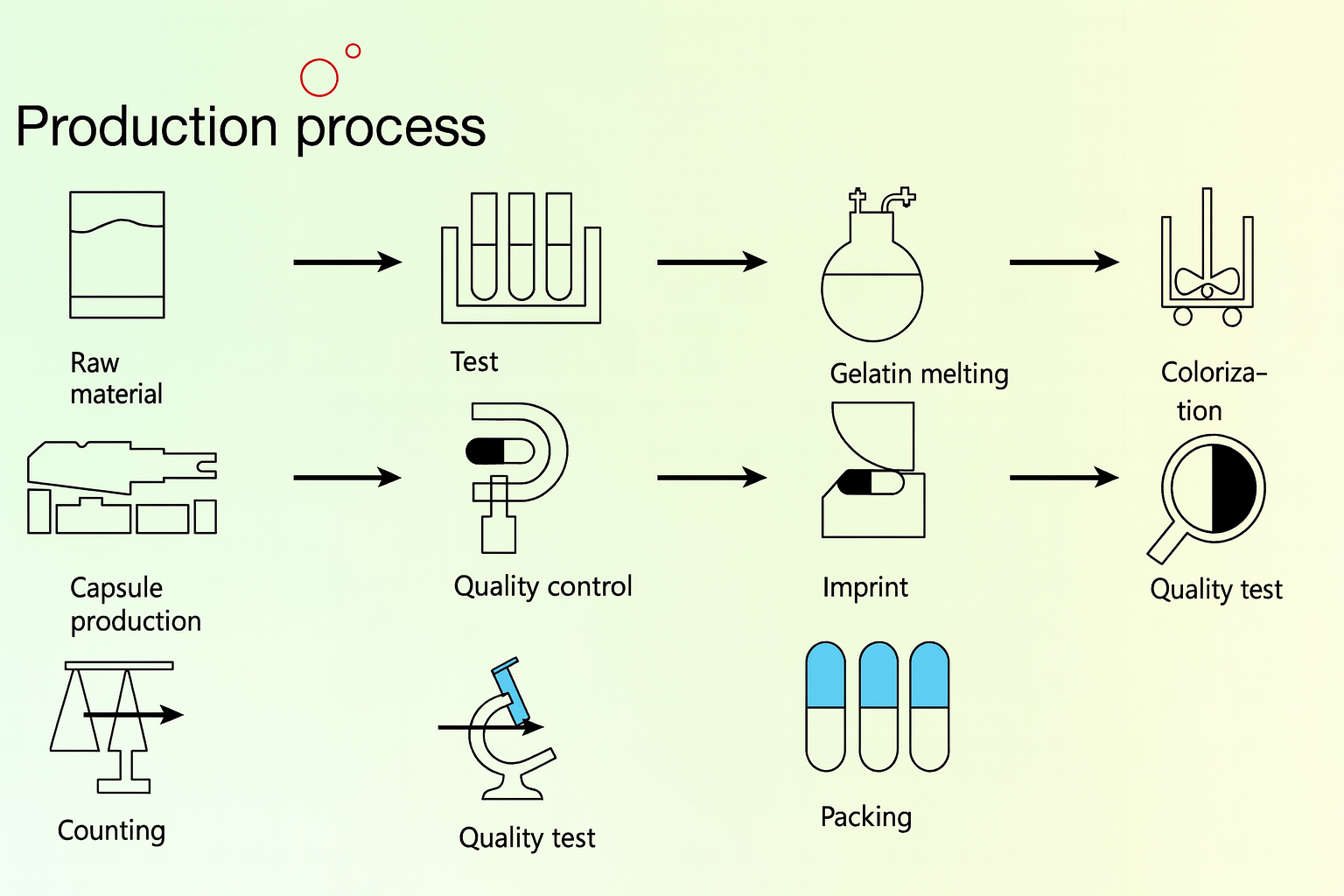

GMP Production Workshop

Our purification workshop is fully enclosed with constant temperature & humidity, featuring:

🌡️ Climate Control

Central HVAC system for optimal production conditions

🔬 Quality Testing

High-tech detection for each production step

🎨 Printing Options

Monochrome, two-color, axial, ring, and directional printing

📋 Full Documentation

Comprehensive batch records and QA monitoring